Over the last decade, we have seen rapid growth within the cannabis industry, both in terms of legalization and commercialization. With this growth, the industry has begun to adopt automation and robotics to streamline operations and increase efficiency. In this article, we will explore the impact of machine automation within the cannabis supply chain and the advantages and disadvantages it presents.

The Cannabis Supply Chain

Before delving into the impact of machine automation, it is crucial to understand the cannabis supply chain. The cannabis supply chain comprises several stages, starting from cultivation and ending with sales to the end customer. The supply chain involves several actors, including cultivators, manufacturers, distributors, and retailers.

Cultivation is the process of growing cannabis, which involves planting seeds, nurturing the plants, and harvesting the flowers. The harvested flowers are then dried, cured, and processed into a variety of products, including edibles, tinctures, oils, and concentrates. These products are then packaged, labeled, and distributed to retailers for sale to end customers.

The Impact of Machine Automation

As the cannabis industry grows, the need for automation and robotics increases. Machine automation can help streamline the supply chain, increase efficiency, and reduce costs. Here are some of the ways machine automation has impacted the cannabis supply chain.

- Cultivation

Cultivation is one of the most labor-intensive stages of the cannabis supply chain. Automation can help streamline cultivation by reducing the need for manual labor. For example, automated systems can regulate temperature, humidity, and lighting, ensuring optimal growing conditions for the plants. These systems can also monitor nutrient levels and water the plants, reducing the need for human intervention.

Automated systems can also help with harvesting. Traditional harvesting methods involve manually cutting down plants, which is time-consuming and labor-intensive. Automated systems can speed up the process by using robots to cut and collect the plants, reducing the time and labor required.

2. Manufacturing

Manufacturing involves the process of turning harvested cannabis flowers into a variety of products, including edibles, tinctures, oils, and concentrates. Automation can help streamline the manufacturing process by reducing the need for manual labor.

For example, automated systems can help with the extraction of cannabinoids, which is a crucial step in the manufacturing process. Traditional extraction methods involve using solvents and other chemicals, which can be dangerous and time-consuming. Automated extraction systems can speed up the process, reduce the need for manual labor, and ensure consistent quality.

3. Packaging and Labeling

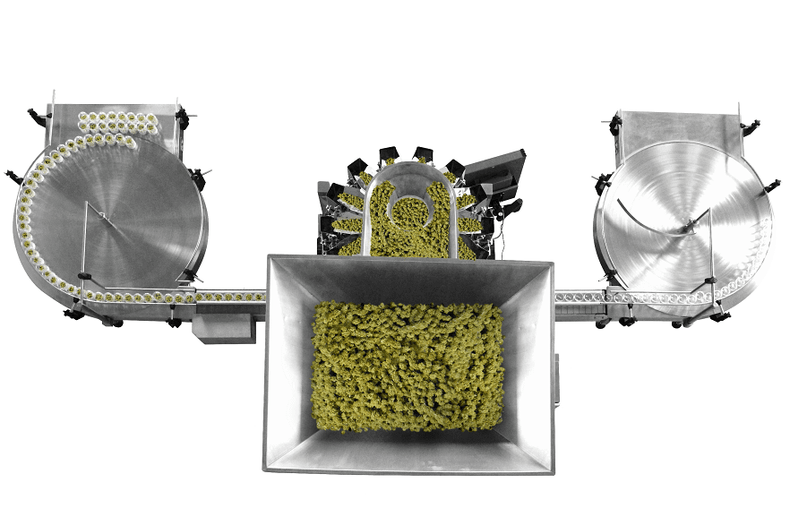

Packaging and labeling are essential stages of the cannabis supply chain. The packaging must comply with regulatory requirements and protect the products during transit. Automated systems can help streamline the packaging and labeling process, reducing the need for manual labor.

For example, automated systems can weigh and fill product containers, apply labels, and seal the containers. These systems can also verify that the correct labels have been applied, ensuring compliance with regulatory requirements.

Advantages of Machine Automation

The use of machine automation within the cannabis supply chain has several advantages, including:

- Increased efficiency: Automation can help streamline the supply chain, reducing the time and labor required for each stage.

- Consistent quality: Automated systems can ensure consistent quality across products, reducing the risk of human error.

- Cost savings: Automation can help reduce labor costs, improve productivity, and increase profits.

- Regulatory compliance: Automated systems can help ensure compliance with regulatory requirements, reducing the risk of non-compliance penalties.

Disadvantages of Machine Automation

While the use of machine automation within the cannabis supply chain presents several advantages, it also has some disadvantages, including:

- High initial investment: The implementation of automated systems can be costly, requiring a significant initial investment