Highest Quality Hardware

The High End Dabzation Ceramic Cartridge.

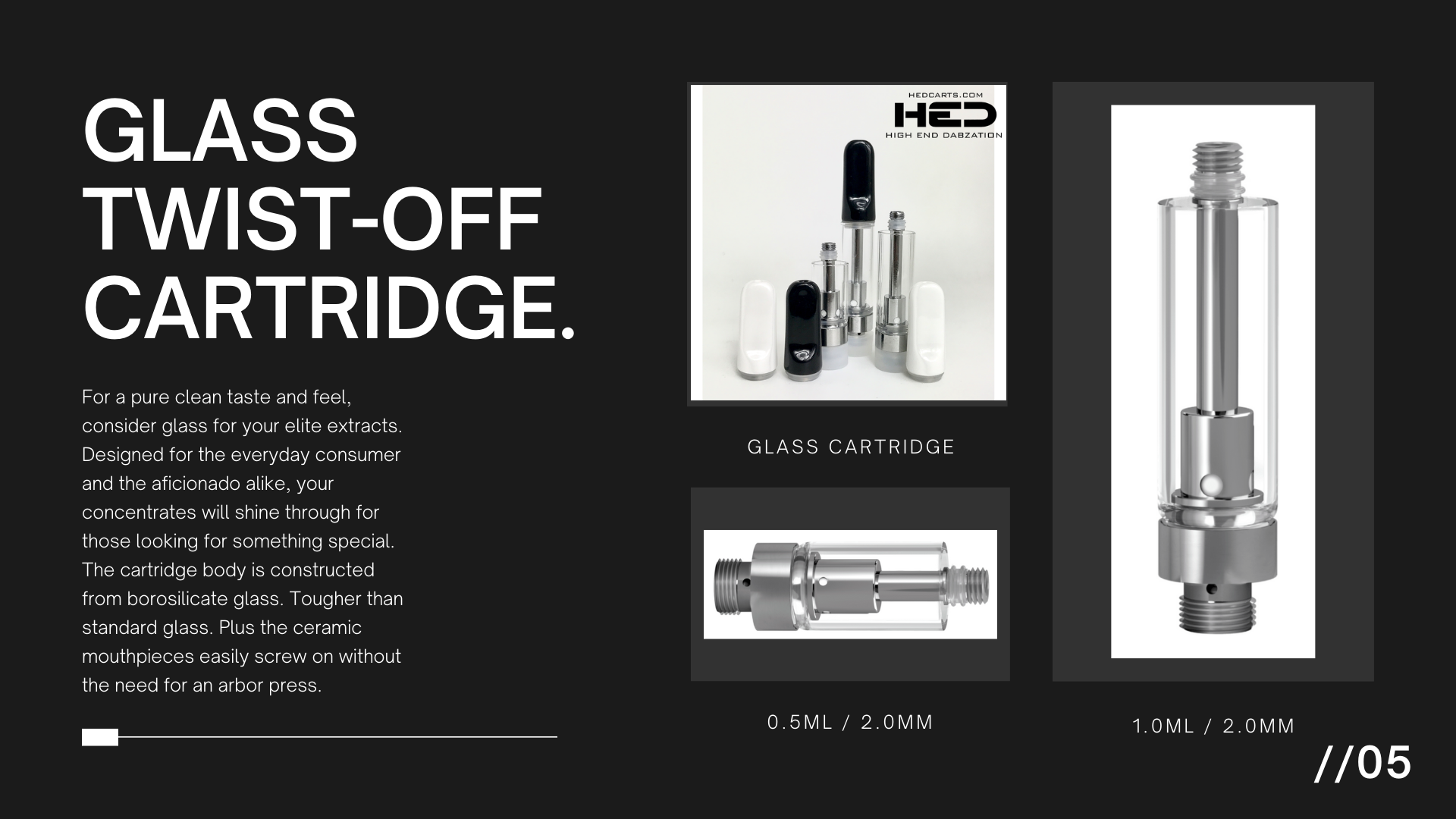

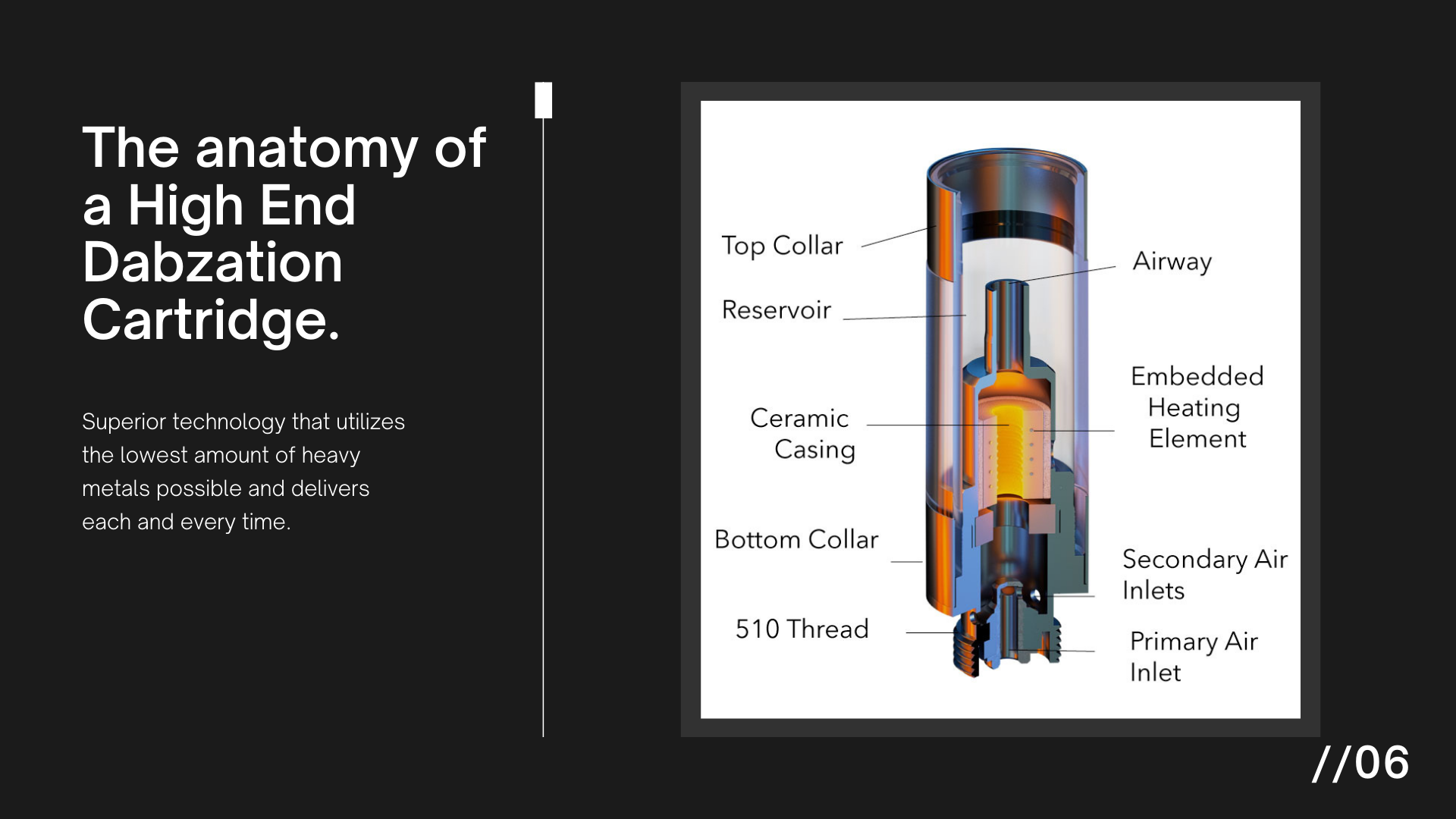

Utilizing only superior raw materials in our sourcing process and complete control over our supply chain; in combination with a cohesive and synergetic relationship with our factory we are able to consistently create ceramic atomizer technology that is far above the rest. The High End Dabzation cartridge is manufactured with a proprietary embedded ceramic coil that is surrounded by an organic cotton filament which allows your oil to be uniformly heated and converted into flavorful clouds of vapor while also protecting the atomizer from malfunctions and leaks.

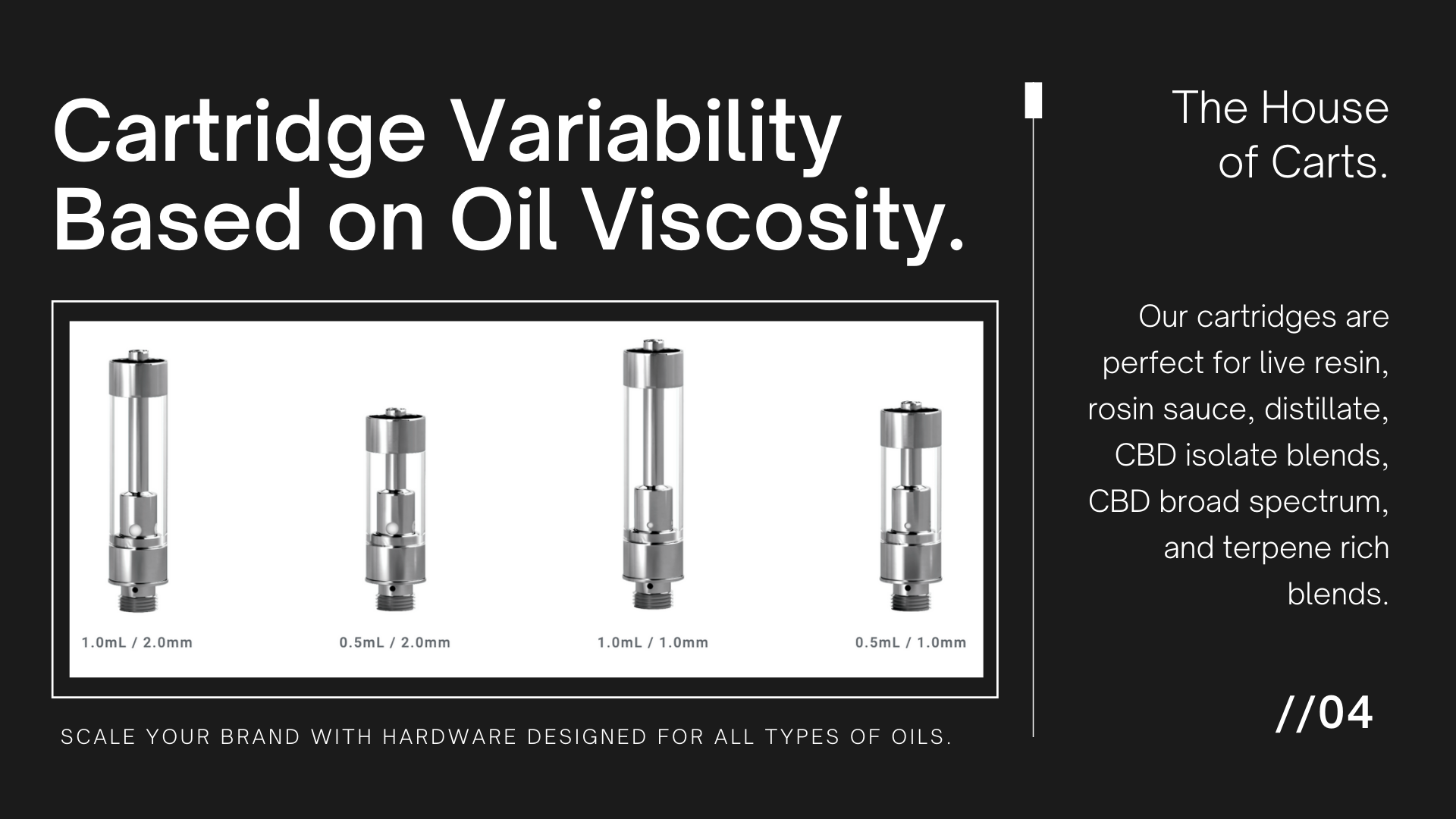

Our cartridges are perfect for live resin, rosin sauce, distillate, CBD isolate blends, CBD broad spectrum, and terpene rich blends.

Whether you plan on throwing a lower viscosity extract into the cartridge such as a CBD dominate concentrate or a super thick heavy THC distillate that’s going to leave you floating in the clouds our carts can perfectly heat any oil. Plus because of our tight knit supply chain our cartridges currently boast a failure rate of 3/1000 carts.

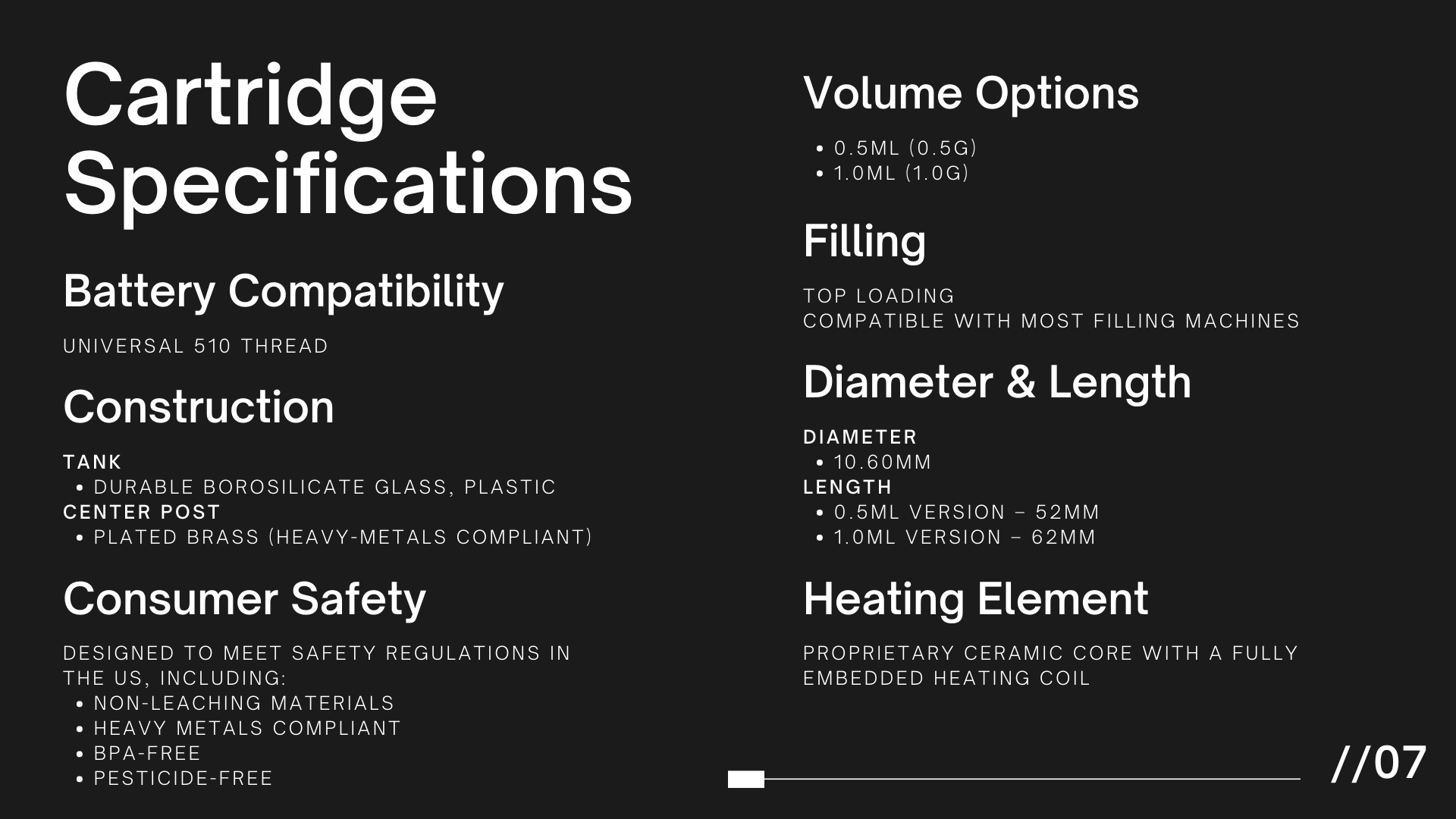

And with safety at our utmost highest priority our carts feature the smallest amount of lead out of any other cartridge in the industry! Lead has been known to cause both cardiovascular and neurological problems and we believe in the power of the medicine you are vaporizing which is why we made our cart the safest and cleanest to encapsulate your oil with. All of our cartridges are guaranteed California CAT III Compliant and are batch lab tested to ensure consistent safety and high quality.

By constantly experimenting, trial, and error High End Dabzation has been able to manufacture a cartridge that enhances the concentrate of both the avid extractor and the everyday consumer while also delivery safe to consume hardware that is non toxic, heavy metal free, and without pesticides avoiding any contaminated oil and failed COA's. True all the way through our cartridges will output consistent Ohm settings to ensure proper temperature control regardless of how many times the cartridge has already been ripped. Meaning flavorful and potent oil for the entire duration of use.

The H E D Cartridge Sealing Press.

By far the most efficient way to press and seal your carts our patented H E D Press will simplify and speed up your cartridge production process. The solid white base is capable of holding all sizes of carts (0.5, 0.8, and 1mL) and can seal both flat tip or round tip via the adjustable white block on the handle. Simply place the cart in the proper spot, place the mouthpiece in place at the top of the cart chamber, pull the lever down, and ‘voila’ what you’ll have is a perfectly sealed cart ready for distribution.

Not only do we take pride in the carts that we manufacture we also take tremendous pride in ensuring our customers have the best tools for sealing and filling their carts which is why we designed this press.

Whether you are buying 0.5mL or 1.0mL carts our press can be used to seal both sizes.

Finally a product on the market that can ensure that when you are sealing your carts they will never leak on your customers or during distribution. Throw out the bulky arbor press that is a pain to use and pick up our press for seamless production.

Branding Opportunities.

We started our business with one product: the chrome cartridge, and have slowly grown into an arsenal of products designed to enhance your concentrates, ease your production process, and simplify your distribution.

While building into these new product categories we have built countless relationships with suppliers within the industry and are able to offer rockbottom whole sale prices on products such as batteries, custom concentrate packaging, and tank branding. In addition we offer an in house graphic design team that is more than capable of taking your dream and turning it into reality.

Typically once a design for either a package or tank is designed upon it only takes about 10 days to produce the final product! You won’t find a better price anywhere else for the quality your brand will be receiving. Get ready for your business to hit the next level.