Vaping has revolutionized the way people consume nicotine and cannabis, offering a safer and more discreet alternative to traditional smoking methods. While vape pens and e-cigarettes come in various shapes and sizes, one crucial component is common to almost all of them: the vape cartridge. Vape cartridges, the vessels that hold and heat the vaping material, are integral to the vaping experience. In recent years, ceramic vape cartridges have gained popularity due to their superior performance and safety features. In this article, we will delve into the fascinating world of ceramic vape cartridges, exploring their manufacturing processes, key advantages, and how they have redefined the vaping industry.

The Evolution of Vape Cartridges

To appreciate the innovation of ceramic vape cartridges, we must first understand their predecessors. Early vape cartridges were typically made of plastic or metal, which posed several issues. Metal cartridges often had a metallic aftertaste, and plastic cartridges could leach harmful chemicals into the vapor. These drawbacks, combined with the growth of the vaping industry, drove manufacturers to develop better alternatives.

Ceramic vape cartridges entered the scene as a solution to these problems. Ceramic, a non-reactive and heat-resistant material, quickly became the material of choice for vape cartridges. Now, let's explore how these cartridges are manufactured.

The Manufacturing Process

- Ceramic Selection: The process begins with the selection of high-quality ceramic material. Alumina (aluminum oxide) is commonly used due to its excellent thermal and electrical insulation properties. The selected ceramic must be pure, free from impurities that could affect the vapor's flavor or safety.

- Molding: Once the ceramic material is chosen, it's molded into the desired shape. The primary shapes for vape cartridges are cylindrical or flat, depending on the manufacturer's design preferences.

- Firing and Sintering: The molded ceramic is then fired at high temperatures in a kiln. This process, known as sintering, strengthens the ceramic and removes any remaining impurities. It also ensures that the cartridge can withstand the heat generated during vaping without deforming or breaking.

- Coating: The ceramic surface is coated with a layer of glaze or enamel. This coating serves several purposes: it provides a smooth, non-porous surface for the vaping material, helps prevent any potential ceramic taste, and adds a layer of protection to the ceramic.

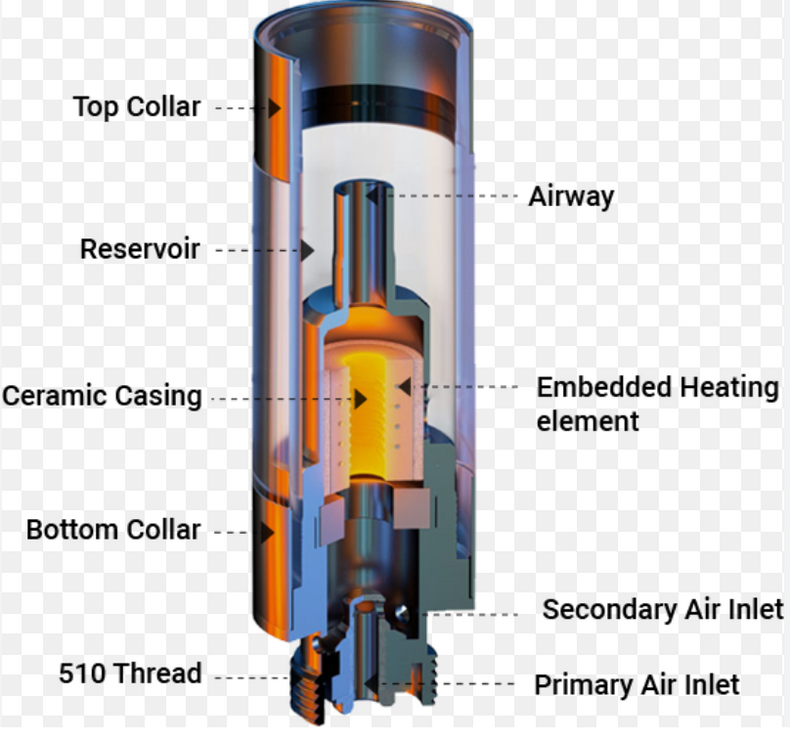

- Heating Element Installation: The heart of the vape cartridge is the heating element, which is installed inside the ceramic chamber. It's crucial that this component is carefully placed and secured to ensure efficient and even heating of the vaping material.

- Sealing and Assembling: The different components of the cartridge, including the mouthpiece, are sealed and assembled. Proper sealing is essential to prevent leaks and ensure the cartridge is airtight.

- Quality Control: Before the ceramic vape cartridges are packaged and sent to market, they undergo rigorous quality control checks. These tests may include checking for leaks, inspecting the heating element, and assessing the overall structural integrity.

Assembling the Cartridge

Once the ceramic components are ready, the assembly process begins:

1. Wick and Heating Element: A ceramic vape cartridge typically consists of a ceramic heating element and a wick. The heating element is crucial for vaporizing the e-liquid, while the wick ensures a consistent flow of the liquid to the heating element.

2. Seals and O-Rings: To prevent leakage and ensure airtightness, various seals and O-rings made from materials like silicone are integrated into the cartridge design. These components play a vital role in maintaining the integrity of the cartridge, ensuring a smooth vaping experience.

3. Mouthpiece and Airflow Control: The mouthpiece, often made from materials like stainless steel or ceramic, is carefully attached to the cartridge. Additionally, modern ceramic vape cartridges come with adjustable airflow control, allowing users to customize their vaping experience.

Advantages of Ceramic Vape Cartridges

- Clean Flavor: Ceramic's inert nature ensures that it doesn't affect the flavor of the vaping material, delivering a purer and more enjoyable experience.

- Health and Safety: Ceramic is a non-reactive material, making it a safe choice for vaping. Unlike some metals or plastics, ceramic does not leach harmful chemicals into the vapor.

- Durability: Ceramic vape cartridges are highly durable and can withstand the high temperatures and pressure associated with vaping.

- Efficiency: The even heat distribution of ceramic ensures that the vaping material is vaporized consistently, preventing issues like hot spots and burnt flavors.

- Customization: Manufacturers can easily customize the design and appearance of ceramic vape cartridges to suit different brands and styles.

Conclusion

Ceramic vape cartridges have emerged as a game-changer in the vaping industry, offering a safer and more enjoyable experience. Their journey from concept to reality involves precise manufacturing processes that rely on high-quality materials and stringent quality control. The advantages of ceramic cartridges, including clean flavor, safety, durability, efficiency, and customization options, have made them a preferred choice among vapers. As vaping technology continues to evolve, it's safe to say that ceramic vape cartridges will remain at the forefront of innovation, providing a more refined and satisfying vaping experience.